R&D / Batch

Our most versatile platform for your processing needs. Powerful, compact design that processes in seconds – not minutes.

What will you make?

The PulseForge Invent is a highly configurable platform with a wide range of Digital Thermal Processing™ applications from academic to advanced R&D.

Printed and flexible electronics are in demand in consumer electronics, particularly in AR/VR, Displays, IoT, Wearables and more. At PulseForge, our customers have a wide range of processing needs that Digital Thermal Processing not only meets, but exceeds.

The PulseForge Invent is the R&D / Batch platform customers can configure to their processing needs and see first hand what innovative, next- gen designs they can bring to life.

What will you make?

The PulseForge Invent is a highly configurable platform with a wide range of Digital Thermal Processing™ applications from academic to advanced R&D.

Printed and flexible electronics are in demand in consumer electronics, particularly in AR/VR, Displays, IoT, Wearables and more. At PulseForge, our customers have a wide range of processing needs that Digital Thermal Processing not only meets, but exceeds.

The PulseForge Invent is the R&D / Batch platform customers can configure to their processing needs and see first hand what innovative, next- gen designs they can bring to life.

Flexible Processing

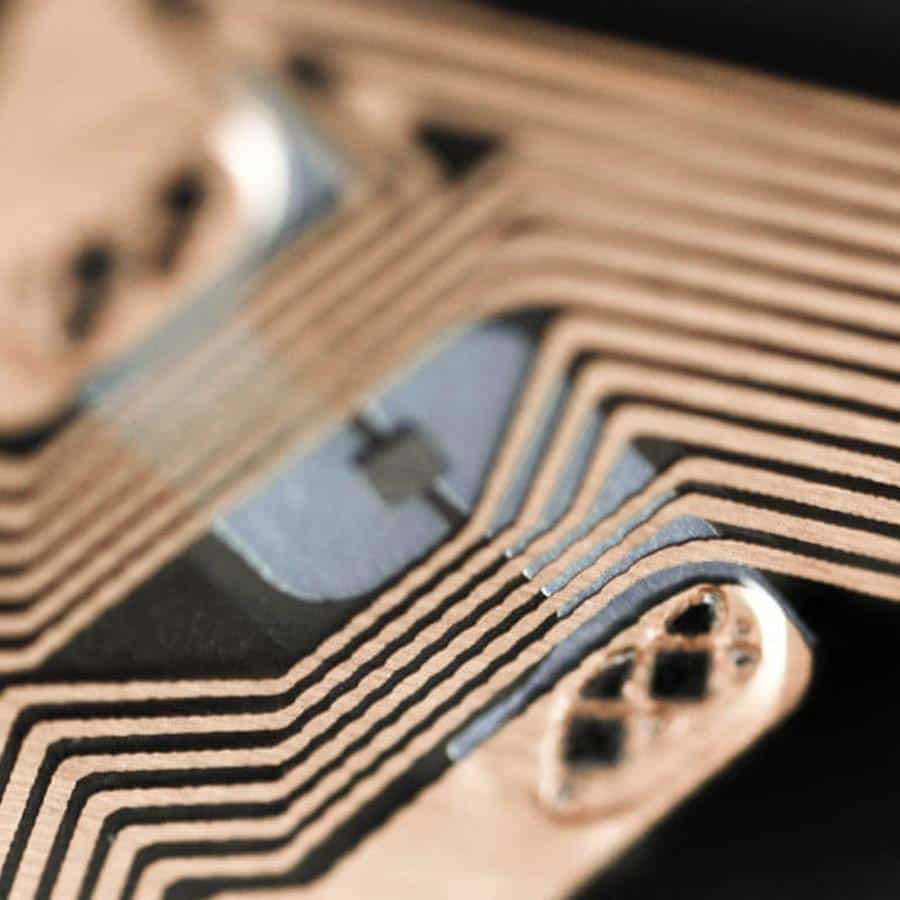

Sintering

PulseForge Invent can sinter conductive silver and copper inks on PET, polyimide, paper or textiles. It is also capable of sintering CIGS and CdTe nanocrystal depositions.

Drying

The PulseForge Invent is capable of drying functional and graphic inks. As well as, drying and sintering plastic coatings.

Crystallization

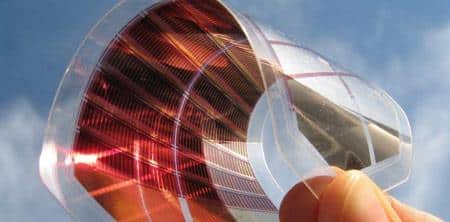

The PulseForge Invent can provide crystallization of perovskite or OPV materials.

Soldering

PulseForge Invent is capable of soldering standard RoHS lead-free solder paste on low-temperature polymers.

Reduction

PulseForge Invent is capable of reducing graphene oxide and copper oxide.

Designed for stand-alone Digital Thermal Processing™

What if you could cure, sinter, and solder on paper, plastic, fabric, or recycled materials? What if you could process ITO for glass, PET, or organic materials? What if you could debond without ash or chemicals? What if we could completely reimagine the thermal process to push innovation and technology while increasing speed, reducing cost, and reducing impact on the environment?

With PulseForge Digital Thermal Processing…you can!

Papers

Fabrics

Thin Glass

Plastics

Perovskite solar cells

Exceeding your thermal processing solution requirements

Whether you are processing for small batch production needs, or in R&D for future, larger production and manufacturing in consumer electronics, transportation, or wearables, PulseForge Invent exceeds your thermal processing solution requirements:

- No damage to heat-sensitive substrates

- Milliseconds to seconds processing

- Small production and eco footprint

- Simulated, predictive tools processing

- Designing with heat-sensitive, less expensive substrates

Find the PulseForge Invent that best meets your individual needs