Curing and Sintering

Cure on Heat-Sensitive Substrates in Seconds, not Minutes!

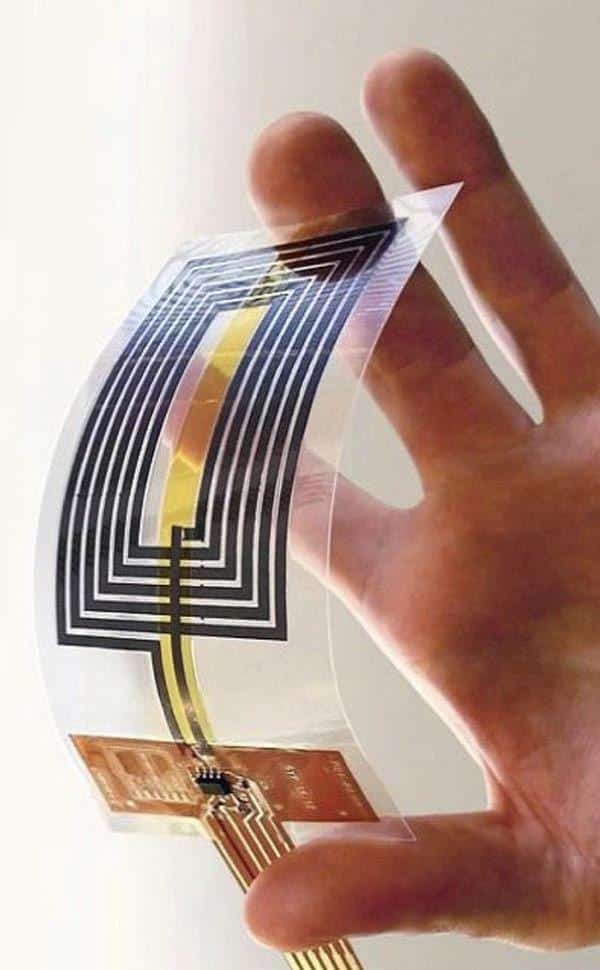

PulseForge Digital Thermal Processing™ provides curing and sintering of thin films at high temperatures on low-cost, temperature-sensitive substrates, including paper and PEN.

Improving Manufacturing

Why It Matters

Ovens

Ovens are slow with lengthy idle warm up and cool down, return low throughput, and have high energy demands

Sustained Heat

Sustained heat of ovens damages heat-sensitive substrates, limiting design and substrate options

Limitations

Substrate and design limitations

Lasers

Lasers offer only one-at-a-time processing

Photonic Curing and Sintering

Why We’re Different

In the manufacture of printed, flexible electronics, PulseForge Digital Thermal Processing™ cures and sinters onto inexpensive, flexible substrates – without damage!

- No warm up or cool down of PulseForge tools

- Substitute expensive glass and ceramic substrates with low-cost, sustainable options

- Seconds processing means substantially higher throughput

- Freedom to design with novel materials

- Higher processing temperatures returns improved conductive performance

And because PulseForge provides curing and sintering of thin films at high temperatures on heat-sensitive substrates, it is the ideal digital thermal process for roll-to-roll processing on polymer and paper.

Growing Application Demands

Layers in devices require versatile thermal processing. Curing and sintering with PulseForge’s Digital Thermal Processing™ is uniquely suited for this manufacturing challenge in next-gen printed electronics:

- Sensors for product tracking in shipping

- Loss prevention in retail

- Display applications for personal devices

- Printed heaters for medical

- SMART packaging

- And more